Greenhouses are magical places, as they envelop you in warmth and provide visuals of lush plant life. This is what you’ll experience at Threefold Farm in Mechanicsburg. However, what’s growing in the greenhouses comes as a complete surprise, especially at this time of the year.

Katherine and Tim Clymer, owners of Threefold Farm in Mechanicsburg, stand among tropical plants that grow in climate-battery greenhouses.

There’s an opportunity in nearby Mechanicsburg for local growers and greenhouse owners to learn a new magic trick to extend growing seasons. While the mission of Threefold Farm is rooted in the Bible (“…make it your ambition to lead a quiet life and attend to your own business and work with your hands” 1 Thessalonians 4:11), its owner, Tim Clymer, is totally attuned to modern technology.

Meeting Tim in his orchard of “unusual fruits,” consisting of kiwi berry vines, pawpaw, fig and persimmon trees, you’d never guess he started as a software engineer. “My love for growing things, especially unusual fruits, wasn’t even a thought in my head when I was in college,” he says, referring to the Rochester Institute of Technology. “That passion began post-college, and my love of fruit trees and unusual fruits was probably birthed when we lived in Texas [2008-2010] and could plant citrus and fig trees outside. My love for design and order was influenced heavily by my education and initial career as a software developer.”

Because of climate-battery technology, Threefold is able to grow tropical plants and fruit during the coldest months.

In 2014, Tim and his wife, Katherine, bought their Mechanicsburg farmland after Tim left his tech job. They started by planting cover crops in 2015, followed by brambles and kiwi berries the next season. In 2017, they planted fig trees and started their first greenhouse. Their growing philosophy is rather straightforward. They utilize organic compost and fertilizers to help build soils that will support healthy plants and in turn, produce healthy produce. They also choose plant varieties that are disease-resistant and tend to require less in the way of sprays.

Star fruit, a tropical variety native to Southeast Asia, offers a texture similar to apples, but with the flavors akin to citrus, pears and grapes.

While the Clymers’ focus is on growing products for wholesale customers, their farm also offers a curiosity that is drawing the attention of engineering students and growers alike: Threefold’s greenhouses.

Greenhouses, The Pros and Cons

Tim and Bill Lauris of Off the Beaten Path Nursery in Lancaster, head for one of Threefold’s greenhouses.

Greenhouses are microclimates that foster plant life and stretch the growing season. Those that take the shape of a more permanent structure will usually require an additional heat source in order to provide warmer temperatures and humidity controls. Such houses are typically oriented south to maximize sunlight and warmth. Extra layers of cold protection – frost blankets and windbreaks in the form of a tree line or other structures – are often utilized.

An alternative is high tunnels, also known as hoop houses, somewhat less permanent structures that usually serve as unheated greenhouses and rely on sunlight for warmth.

There are inherent limitations and extra work required to operate a greenhouse. If frost blankets are placed over plants at night, they must be removed later to prevent mold and withering heat in sunny conditions. Heating a greenhouse over winter with gas or electric heat is expensive. Add in an unusually cold winter and escalating operating costs and you have the answer why the plants you buy each spring seem to grow more expensive.

At Threefold Farm, warm-season temperatures in a greenhouse can reach “120 degrees if you keep it fully sealed,” says Tim. “You have to open something to flush out that excess heat and avoid baking your plants. But at night, when the sun starts to go down, you have to button it all up and then throw a bunch of propane heat or some kind of heat in it. You’re throwing out a ton of heat during the day, then you’re buying heat at night. It just doesn’t make sense,” he says. If only the mid-day heat could be removed, captured and released at night. Hmm.

Climate Battery

Tim landed on an alternative solution that enables problems to work together. Known as a climate battery, the basic idea is to regulate temperatures for heating (and cooling) by warming the soil with an underground radiator. “The goal of the climate battery is to push heat underground at the same rate it’s being produced by the sun,” he points out.

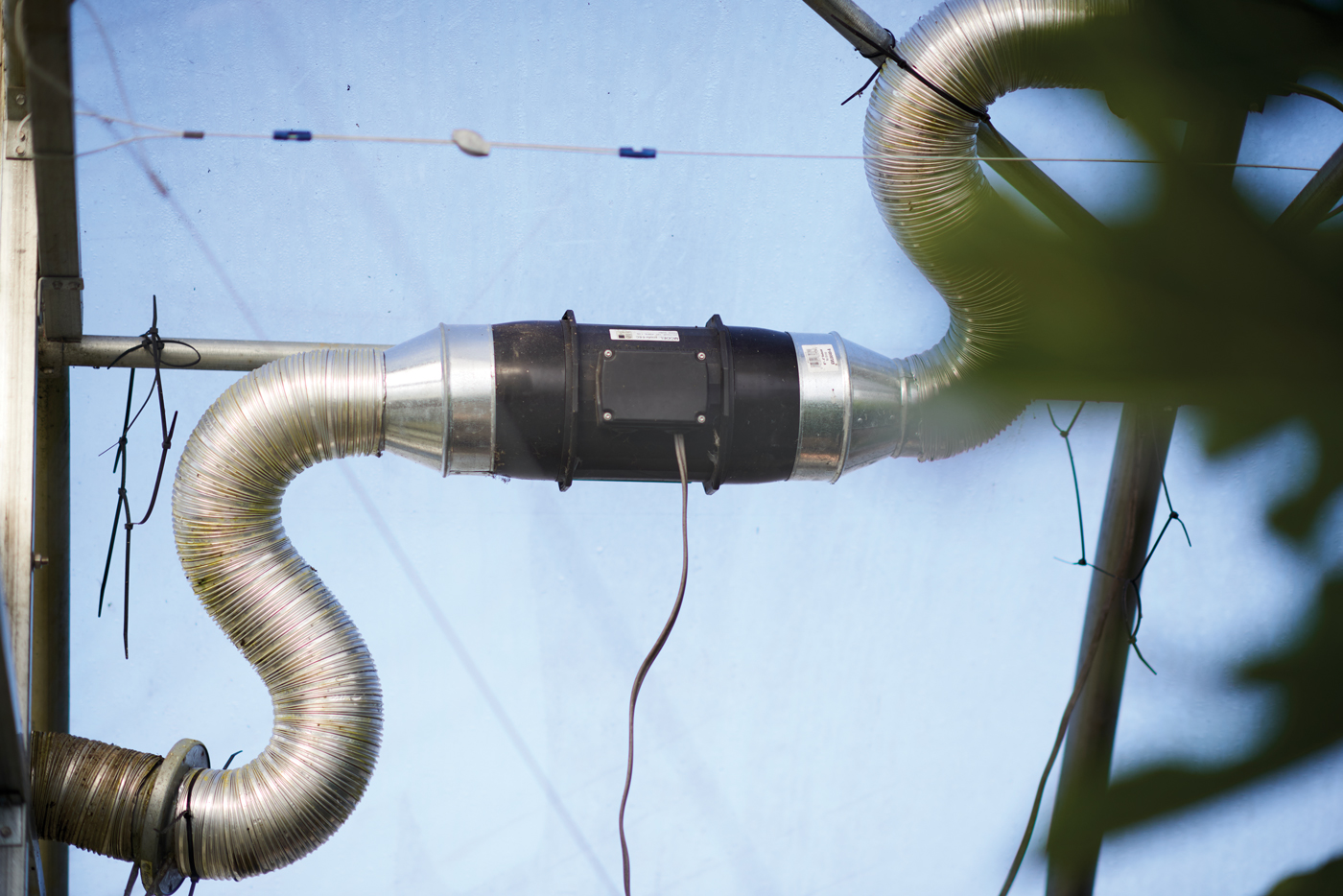

A plastic inflation fan is used to add air space for insulation between two layers of plastic in the greenhouse covering. Paired with a climate battery, the set-up reduces the amount of manpower that is needed to keep the greenhouse from freezing or overheating.

By using electric fans attached to an optimized system of pipes buried directly beneath the greenhouse, excess mid-day heat is removed from the greenhouse. As warm air circulates through the cool soil, the air temperature lowers as the soil warms. With the heat transferred to the soil, fans circulate cold air back at night through the warmer soil, raising the air temperature in the greenhouse without the expense of burning fuel. Win-win. How growers utilize that stored heat depends on their application and climate. While Tim doesn’t use a secondary heat source, one could be installed as a backup or for extreme winter conditions.

Tim was not the first to invent the idea of a climate battery; it was his goal to develop a more compact, efficient implementation that could be repeated. “I heard about some guys in Colorado who were doing this kind of battery, as well as another guy in Nebraska,” Tim explains, referring to Russ Finch, who was an early climate or “earth battery” pioneer and grows citrus, grapes, pomegranates and fig trees in an otherwise brutally cold region.

Finch’s “Greenhouse in the Snow” concept differs in that his greenhouses are built partially underground, with radiator pipes buried 8-feet deep and running in a large loop outside the foundation. That specific low-grade geothermal system creates a farming advantage: lower shipping costs. Citrus grown in Nebraska eliminates the need for products to be shipped in from a warmer climate hundreds of miles away.

Large drain culverts (with 24-inch fans) cycle air through the greenhouses. The air serves to cool the houses during the heat of the day and is stored for warming purposes on cool nights.

However it’s done, the installation is an investment, but the operational costs offset the expense in the long run. Climate batteries require less labor, deliver a longer growing season and save fuel costs. The point becomes clear when comparing energy use. “A propane heater has a burner attached, which is only so efficient at converting chemical energy to heat energy,” says Tim. “The higher ones are around 90%. It’s pretty good, but they also have distribution [fans] attached. They’re expending 800 or 1000 watts just pushing that heat out into the greenhouse. So, for 1,500 to 2,000 watts, I’m essentially doing the same thing. I’m extracting heat and pushing it around the greenhouses,” he says.

Elaborating on the efficiency, Tim uses a term called the “coefficient of performance” (COP) or a “ratio of energy out to energy input.” Therefore, a COP above one means that you’re getting more energy out of the system than you put in. “A space heater, for example, is one-to-one, as it perfectly converts electrical energy to heat energy,” Tim explains. “Heat pumps essentially extract heat energy from the air outside, they’re [achieving an] efficiency of two or three to one. Geothermal is better, maybe they’re at four or five in terms of the coefficient.” For the climate battery, “We did some early calculations and it’s certainly north of 10 to one. I think it’s somewhere like 30 to one,” he says.

Gray & Blue Houses

Threefold Farm has two greenhouses equipped with climate batteries that represent different design generations. “I come from the software world where the cost of iteration is very low,” Tim points out. “If I want to change a couple of lines of code and see what it does, seconds later I can test that. The feedback loop is immediate,” Tim continues, noting that technology moves at the speed it does due to software. “There’s not that luxury here,” he adds.

Each of Threefold Farm’s greenhouses gains roughly two USDA Zones in the wintertime. That protected climate is similar to Florida’s Zone 9A and 9B, growing tropical varieties and tender perennials, but in Pennsylvania. Working in conjunction with the climate battery, fans are programmed on a thermostat to automatically vent excessive heat during peak hours in the summer, lowering the time and labor commitment to manage the greenhouse.

Tim inspects a rare fig tree variety named “Threefold Variegated” that exhibits partially variegated leaves, fruit and lignified branches.

“The Gray House is the first iteration [2017] and is the one that contains all the tropicals and has the windscreen. The Blue House [34×96 feet in size] is the second iteration [2018] but was done before we knew what we were doing tubing-wise,” Tim explains. “Both required large rocks to be excavated. The Blue House also uses over 2,000 watts now with the addition of new fans and booster fans. The Gray House uses something like 1,800 watts and is a more efficient design but by no means is it perfect.”

After taking a trip to Florida, Tim was inspired to begin growing tropical plants in the Gray House. It’s here that avocado, starfruit, lychee, banana plants, jackfruit, eucalyptus, lemons and limes grow. Inside the house, 24-inch fans and 18-24-inch-diameter drain culverts cycle the air 15.63 times per hour using 1,100 watts. By comparison, a central air conditioner for a 2,000-square-foot residence might use several thousand watts.

Figs grow in the Gray House, where the climate battery is equipped with smaller (6-inch) manifolds. A double cordon-and-spur training method is used to allow for branches to grow horizontally.

Fig trees grow as well, using a double cordon-and-spur training method unheard of in northern climates. This method is similar to espalier pruning used in vineyards to maximize space, light, airflow and grape yield. Avoiding dieback every winter, the fig tree trunks are abnormally large. Two massive branches extending 16 feet in diameter grow horizontally a few inches above the soil. Using thinning cuts, the branches are spaced to grow vertically every 12 inches.

Where to Find Threefold Fruit

- Talking Breads Bakery, Mechanicsburg, talkingbreadsbakery.com

- Basehore Farm, Mechanicsburg, basehorefarm.com

Where to Start

Tim underscores that the most efficient implementation takes place in a greenhouse before construction, not retrofitting established greenhouses. Having access to a backhoe will lower installation costs.

Through a separate company, Atmos Greenhouse Systems, Tim sells climate-battery blueprints. Installation is up to the grower and a build sheet is included with estimated costs for project planning. Tim also offers a separate consultation service to consider more specific growing needs. Plans are available for standard greenhouses at 24- and 30-feet-wide by 48-, 72- or 96-feet- long.

“I try to be genuinely helpful to people who want to learn more about these systems,” says Tim.“I’m convinced it’s a really promising solution for a lot of people.”

Visit threefold.farm and atmosgreenhouse.com for more information.

SHARE

PRINT