Lancaster Cast Iron’s largest pan, the No. 12, joined the No. 8 and No. 10 pan sizes in October. All are on display in the company’s store in Conestoga. Hint: cast iron pans make great wedding gifts.

The popularity of cast iron cookware continues to grow with home cooks and professional chefs alike. Excellent for baking, searing, grilling, frying and stewing, there are countless YouTube channels and forums dedicated to cast iron skillets. The town of Conestoga is home to a company that is helping to make something old quite new again: Lancaster Cast Iron.

The Road to Alaska

In July of 2018, longtime Grove City College friends, Mark Longenecker and Brandon Moore, set out on the road trip of a lifetime. Heading for the Arctic Ocean in Alaska, the trip would also mark a transition, as they had departed from traditional career roles in marketing (Brandon) and manufacturing (Mark). “We drove every road in Alaska, all the main roads in Alaska,” says Brandon. Averaging 12 to 14 hours a day in the car, the two racked up 15,500 miles in two months.

The trip would also allow them to indulge in some brainstorming. “Both of us were passionate about the idea of starting a business,” Mark explains, adding, “We had talked about cast iron for a long time.” Discussing an assortment of issues and how they might solve them, they went as far as writing multiple business plans. Just as cast iron has endured for centuries, discussion of a business dedicated to cast iron skillets endured long after their trip ended.

Lancaster Cast Iron’s co-owners Brandon Moore (left) and Mark Longenecker inside their factory store along Main Street in Conestoga.

Developing their proposed skillets became their next challenge. “We wanted to bring back that lightweight and smooth cast iron,” says Mark, who grew up in Conestoga, where the family kitchen was equipped with 100-plus-year-old skillets. He knew the difference between those heavy, rough skillets and the thinner, smoother and lighter designs they were proposing. “We felt that market wasn’t being reached very well. We spent almost a year before the Kickstarter [campaign] talking to people at foundries, machine shops and anyone we could get connected to who would give us their thoughts, that we could learn from. Neither of us had a background in this industry. I was involved in manufacturing, but not iron. Processes but not materials,” he points out.

Kickstarting the No. 8 Cast Iron Skillet

To raise funds to produce their first skillet, Brandon and Mark turned to crowdfunding. “We officially launched our Kickstarter on June 25, 2019,” says Brandon. Twelve hours later, they were fully funded. “A month later, we raised $35k, which helped us fund that initial manufacturing run,” he adds. With a match plate made, they started shipping the No. 8 skillet by Christmas of 2019. (According to Lancaster Cast Iron’s website, “Historically, cast iron sizing was associated with the “stove eye” or opening of a wood stove. The numbers used have no direct correlation to the dimension of the pan or cooking surface. We decided to keep the sizing metric as a tribute to this American tradition.”)

Mark showcases the inlaid Conestoga wagon with “Lancaster, Pennsylvania, USA” that’s included on the back of the No. 8 cast iron skillet.

“Due to limitations of spacing, we did not have the room to bring in more products other than the No. 8 because it blew up,” Mark recalls. “We were renting a house with a tiny workshop. We were living with the business. [Customers] would stop by the house we were renting. We had a number of people show up, [including] a family from Seattle. They were desperate to meet us and didn’t care that we worked out of our house. They came and bought a skillet,” he says. “It was a lot – to live together, to work together – but we did it for two-and-a-half years.”

The Process

“It was like walking through a canyon to go from the front door to the kitchen,” remembers Brandon. “We were seasoning all of our skillets in our kitchen, so we didn’t have use of it for weeks on end. We would go down to Mark’s parents’ house, and his mom would make us food.”

That all changed in 2021, when they purchased their current location (a former schoolhouse) on Main Street in Conestoga, which includes a much-needed storefront.

Opening a factory store happened almost out of necessity, as customers would show up at their home hoping to buy a pan. When they secured the Conestoga location (once a schoolhouse), including a retail store made sense.

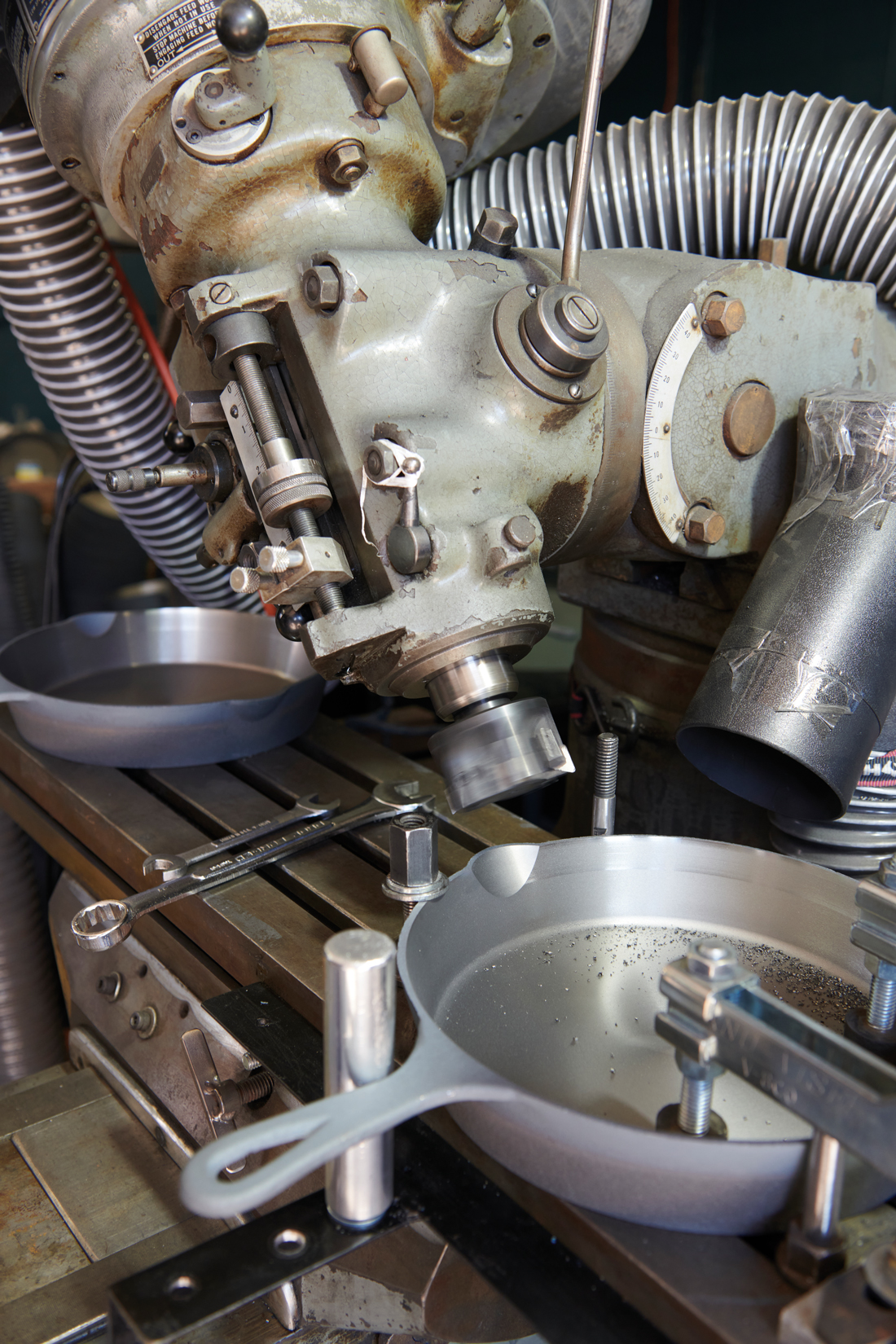

Lancaster Cast Iron has since added a No. 10 and No. 12 skillet. A pattern for a smaller No. 4 pan is in development; long-term plans call for developing a No. 6 and, potentially, a Dutch oven. “We do all the engineering work in-house,” says Mark. “Brandon taught himself CAD [computer-aided design]. He does all the design work, and we work with a company to CNC [computer numerical control] a match plate out of his design. It typically takes about two months; it’s mostly lead time. Whether it’s with packaging, machining, working with foundries, it’s definitely beneficial to work with people that are [located nearby] because you can meet with them face to face. It’s easier to build relationships and trust, and that’s served us well.”

Overcoming Obstacles

At the start, the mix of excitement and optimism propelled Brandon and Mark through countless obstacles. “It’s a super-old industry,” Brandon remarks. “Two young guys like us walking in the door, Mark’s gotten laughed out of offices before. It’s trying to build that rapport and relationship that was the key to our initial success, and even ability to get started,” he says. “When they’re dealing with accounts they’ve had for 50 years and they make 50,000 pieces a year, they don’t care about these really small drops in a bucket trying to make a handful of pieces to get started with.”

The store also stocks items such as cooking utensils, cutting boards, seasoning needs for pans, herbs and more.

“Finding the right foundry for the right product is much more difficult than we realized,” Mark reports. With thousands of foundries in the United States, “Some can make very wide things, but not very deep things, or vice versa,” he says. “Some focus on quality, some on quantity. There’s a wide range of methods that foundries utilize for their production, whether they’re heating with electric or gas.”

According to Mark, “The casting is difficult, but pushing iron to the extreme is challenging. Iron does not like to naturally be pushed to the limits that we push it to, meaning the thin wall. We wanted to pursue the benefits that the antique brands like Erie, Griswold and Wagner offered, which was a thinner, smoother, lightweight pan for anyone to use that also responds to heat well but has the natural benefits of cast iron’s heat retention. We pursued that – a little naively at first – but then learned how difficult that was to truly achieve. Over time, we made small advances, and got to the product that we have today.”

Carol Wiggins, Mark’s “Mommaw,” delivers locally sourced beeswax used in conditioners for cast iron pans, wood utensils and cutting boards. Carol and her husband, Russ, want to see Mark and Brandon succeed and therefore help with an assortment of jobs around the business that ranges from pickups and deliveries to weeding around the building.

Durability

Seasoned cast iron is nearly indestructible, making it an enduring heirloom piece of cookware. Acidic foods, as well as rust, can etch and pit the surface. Perhaps the greatest issue revolves around temperature shock. Pouring cold water on a hot pan can cause the metal to cool unevenly, leading it to spin or wobble on a flat surface. On a gas range, warped pans will be more stable, but food might slide with an uneven surface. Additionally, bringing too small of a heating element up to temperature too quickly can also cause warping. Heat and cool the pan gradually, and it will serve you well for decades.

A croissant dough, cream cheese cinnamon roll baked in a No. 8 skillet is the cure for a cold winter’s day. Warm aromas of cinnamon, vanilla, sugar and bread tease the senses as the bake finishes.

Croissant Cinnamon Roll with Cream Cheese Icing Dough

NYT Croissant recipe from Claire Saffitz

Ingredients

For the Détrempé (dough)

- 4-2/3 cups all-purpose or bread flour, plus more for dusting

- 1/3 cup granulated sugar

- 1 Tbsp. plus 1/2 tsp. kosher salt

- 2-1/4 tsp. active dry yeast

- 3/4 cup plus 2 Tbsp. water (at room temperature)

- 1/2 cup whole milk (at room temperature)

- 1/4 cup unsalted butter, cut into 1/2-inch pieces, chilled

For the Butter Block and Assembly

- 1-1/2 cups unsalted European or European-style butter (3 sticks), chilled

- All-purpose flour, for rolling

- 1 large egg yolk

- 1 Tbsp. heavy cream

Directions

Mix dough, cover with a towel, let rest on counter for one to two hours. Refrigerate for several hours, or overnight.

Evenly roll out three sticks of cold butter between large pieces of parchment paper until 1/4” or thinner. Refrigerate on baking sheet.

Roll out dough, add butter block. Fold, then chill for an hour. Repeat one more time.

Filling Ingredients

- 1 stick butter (4 oz)

- 1 cup dark brown sugar

- 1.5 Tbsp. ground cinnamon

Directions

Brown 1 stick of butter (I used a small cast iron skillet; size No. 3 or No. 4 would be better). Add dark brown sugar and ground cinnamon until melted and well mixed. Chill, allowing to totally cool.

Roll out dough into long 1” to 1.5” thick slices, depending on the height of the skillet.

Add filling with a spatula in even layers.

Grease No. 8 skillet with butter and wrap dough in a circle, joining.

Preheat oven to 350 F. Bake for approximately 70 minutes and allow to cool.

Tip: if the dough doesn’t quite make it to the edges of the skillet, that’s fine. As the laminated dough expands and the butter creates pockets of air, it will conform to fill the pan with flaky dough. With over a pound of butter, the laminated dough expands and bubbles when heated. Your bake time may vary.

Cream Cheese Icing

- 8 oz. Philadelphia Cream Cheese

- 1/3 cup confectioners’ sugar

- 2 oz. milk or cream

- Vanilla extract (scant teaspoon)

Lancaster Cast Iron is located at 3340 Main Street in Conestoga. Visit lancastercastiron.com for more information.

What a great story! Those are beautiful pans, Well done!